- Services

- Surfaces

- Knowledge Bank

- Added Value

- WIOPedia

- Abrasion

- ABS

- Acid resistance

- Acidic cleaners

- Active surface

- Additives

- Adhesion

- Adhesion Coating

- Adhesiveness

- Ag (silver)

- Alloy deposition

- Aluminium

- Aluminium finishing

- Ampère

- Ampere-hour (Ah)

- Anode

- Anode bag

- Anodic corrosion protection

- Anodic degreasing

- Anodic oxidation

- Anodising

- Anodized

- Anodizing

- Anodizing colored

- Anodizing process

- Eloxalprozess/Anodizing process

- Aqua regia (aqua regis)

- Auxiliary anodes

- Auxiliary cathodes

- Bad

- Ball impact test

- Ball indentation according to Erichsen

- Barrel goods

- Barrel plating

- Basic exposure values

- Bath voltage

- Black chromating

- Black surface

- Black oxidation of stainless steel

- Black oxidizing stainless steel

- Blasting media

- Brass

- Bright chrome plating

- Brightener and brightener additive

- Bound cyanide

- Burning

- Carburising

- Carbonitriding

- Carbonitriding layers

- Cascade flushing

- Cast steel blasting / steel shot blasting and blasting in general

- Casting

- Cataphoretic dip coating

- Cathode

- Cathodic corrosion protection

- Cathodic degreasing

- Catholyte

- Cations

- Cellulose acetate

- Centre conductor effect

- Centre line

- Centre roughness value

- Cermets

- Chemical high phosphorus

- Chemical medium phosphorus

- Chemical resistance tests

- Chemical shining / chemical polishing

- Chemically unstable surface

- Chlorinated rubber

- Chromating

- Chromatography

- Chrome

- Chrome plating

- Chrome separator

- Chromic acid process

- Circulating air drying

- Cleaning

- Cleaning agents

- Climate testing equipment

- Coating

- Coating corrosion

- Coating thickness and strength

- Coefficient of friction

- Coil-Coating

- Cold degreasers and cleaners

- Colloid

- Colored anodizing

- Coloring of metals

- Compaction

- Conductive lacquers

- Conducting salts

- Conductivity, electrical

- Contact corrosion

- Conversion coatings

- Corroded surface

- Corrosion

- Corrosion-protective coatings

- Cost Engineering

- Coulombmeter

- Coulometric layered ceiling measuring method

- Covering capacity

- Copper (CU)

- Copper plating

- Copper-nickel coating

- Co-deposition of hydrogen

- CO2 pellets

- CO2 snow

- CO2 snow blasting

- Cracked or torn surfaces

- Cracks

- Crosscut

- Cryo

- Cryogenic process

- Current density

- Current density-potential curve / current voltage curve

- Current yield

- Cutoff wavelength (profile filter)

- CVD process - Chemical Vapor Deposition

- Cyanides

- Cyanogen, dicyanogen (CN)2

- Cyantesmo test paper

- Deposition rate

- Deionised water

- Decapitation

- Demineralised water

- Depolarisation

- Distillation

- Diaphragm

- Diffusion

- Diffusion layer

- Dip Coating

- Dispersion

- Dispersion deposition

- Dissociation

- Double layer (electrochemical)

- Ductility

- Decorative coatings

- Design-to-cost

- Ductile - Ductility

- Ductile surface

- Duplex system

- Degreasing

- Deburring

- Decoating

- Dezincification

- Descaling

- Designing for electroforming

- DC sputtering

- Dimensional coating

- Dry ice blasting

- Drying

- Dimensional Tolerance

- Demineralised water

- Etching

- Evaporation in a high vacuum

- External currentless metal separation

- Electroless nickel / electroless nickel plating

- Electroless nickel solderable

- Electroless low phosphorus

- Electrical conductivity

- Electrical layer testing

- Electrochemical deposition

- Electrode potential

- Electrolysis

- Electrolyte

- Electrolytic degreasing

- Electrolytic deburring

- Electrolytic derusting

- Electrolytic polishing

- Electrolytic hardening

- Electrolyte monitoring

- Electron Microscope

- Electropolishing of metal surfaces

- Electrocoating

- Electroless Nickel (EN)

- Electroplating (a.k.a. electroplating)

- Electroplated nickel bright / bright nickel

- Electroplating

- Engraving

- Electroless metal deposition

- Efficiency

- Embrittlement

- Flaking

- Filling porous workpieces

- Faraday's laws

- Fast Speed Plating / High Speed Plating

- Functional coatings

- Food-safe surface

- Friction tinning or galling

- Germination

- Gloss level surface

- Glass bead blasting

- Galvanic potential

- Galvanic forming

- Gas chromatography (GC)

- Gas phase cleaning

- GFC

- Gloss

- Gloss range

- Gloss formation

- Gloss measurement of coating films

- Glass metallization

- Glow discharge

- Gold

- Gradient layer

- Green chromating

- Grinding

- Grinding method

- Gilding

- Goods carrier

- Galvanising

- Hard and wear resistant surface

- Hardness

- Hardening

- Hard chrome plating

- Hull cell

- High Phosphorus

- Hardness grade of surface

- Hollow microspheres

- Hydrogen embrittlement

- Iron

- Initial sample test report

- Inert surface

- Infrared spectroscopy

- Inhibitor

- Internal stress

- Intercrystalline corrosion

- Ions

- Ionise

- IR drying

- Improved abrasion resistance

- Improvement of chemical resistance

- Improving gloss level

- Improving corrosion protection

- Improving conductivity Aluminum

- Improvement of solderability

- Improving UV resistance

- Interface

- Interfacial mixing

- KTL

- Levelling

- Limit concentrations

- Lapping

- Laser

- Light microscope

- Local element

- Layer testing (electrical)

- Low phosphorus

- Layer thickness of thick film passivation

- Making aluminium components conductive

- Mandrel bending test

- Magnesium (Mg)

- Magnetic abrasive finishing

- Magnetron sputtering

- MAK value

- Manganese (Mn)

- Machinery Directive

- Masking

- Mechanical coating film properties

- Mechanical tests

- Medium-solid lacquers

- Multi-component lacquers

- Metallic effect paints

- Metallography

- Metal organic CVD

- Metallic pigments

- Microhardness according to Fischer

- Micrometer

- Microwave drying

- Minicoat and Maxicoat processes → Powder sintering processes

- Möbius cell

- Modified alcohols

- Mohs hardness

- Molecular weight

- Molybdenum (Mo)

- MOS

- Multilayer technology

- Multilayer coating

- Mercury (Hg)

- Nanometre - nm

- Nanoparticles

- Nanotechnology

- Neutral degreasing

- Neutralisation

- Neutral cleaner

- Non-ionic surfactants

- Nickel (Ni)

- Nickel Phosphorus

- NiP

- Nitrocarburi layers

- Nickel plating

- Ohm's law

- Orange peel effect

- Orange peel texture

- Organic coatings

- Organic solvents for metal cleaning

- Osmosis

- Oxidation or oxidizing

- Pickling

- Pickling degreaser

- Pickling inhibitors

- Pickling brittleness

- Printed circuits

- Primers

- Plastic electroplating

- Pitting corrosion

- Palladium

- Partial anodizing / anodizing

- Passivity

- Patina

- PECVD (PACVD)

- Periodic table of the elements

- Peroxides

- pH value

- Phenolic resins

- Phosphating

- Photoprinting / photo printing

- Photoinitiators / Photoinitiators

- Photometry

- Physically drying coatings

- PIBD Plasma asisted IDN Beam Deposition = Ion Beam Deposition

- Pigments

- Pitting

- Plasma

- Plasma Activation

- Plasma etching

- Plasma CVD

- Plasma diffusion, plasma heat treatment

- Plasma polymerization

- Plasma-PVD (Plasma-Physical-Vapour Deposition)

- Plunge grinding

- Plasticiser

- Post-treatment in electroplating

- Ply corrosion

- Racks

- REACH

- Rectifier

- Redox potential

- Red rust

- Reference electrode

- Residual stress

- Rockwell hardness test

- RoHS compliant

- Roller burnishing

- Roughness profile (R-profile)

- Rust

- Rust surface / coating

- Reverse osmosis

- Sliding properties

- Shine

- Smoothing depth Rp

- Smooth rolling

- Surface-active substances

- Surface adhesion

- Solderable coating

- Solid solutions

- Surface activation

- Surface abrasion resistant

- Surface chemically unstable

- Surface gloss

- Surface does not adhere

- Surface not tacky

- Surface not solderable

- Surface bursts and/or cracks

- Surface hardness too low or increase on aluminium, non-ferrous metal, steel.

- Surface roughness testers

- Surface tension

- Surface technology

- Sacrificial effect

- Surface too soft

- Scanning electron microscope/ie

- Scoring test

- S-Nickel

- Salt spray resistance / salt spray test

- Sandblasting

- Sealing

- Silk matt surfaces

- Selective coating

- Silver

- Silver hard / Silver soft

- Sn - Tin

- Sol-gel process

- Stress corrosion cracking

- Spectroscopy

- Spray painting

- Sputtering

- Spreading ability

- Substrate

- Surfactants

- Silver plating

- Tarnishing

- Thick film phosphating

- Thin-film technology

- Through-hole plating

- Total measuring section

- Tampon electroplating

- Tape Test

- Temperature-resistant surface

- Temporary corrosion protection

- Titanium

- Transparent passivation

- Tinning

- Tartar

- Tin (Sn)

- Tensile stress

- Tinder

- Ultrafiltration

- Ultrasonic cleaning

- UV-resistant surface

- UV weathering

- Vibratory grinding

- Verdigris

- Voltage series of the elements

- Vacuum coating process

- Vanadium (V)

- Velour nickel

- Volt

- Vickers hardness test method

- Viennese lime

- Water stains

- Watts nickel electrolyte

- Wetting

- Wetting test

- Weighting function

- Wet process

- Wetting agent

- Wear-resistant surface

- Whisker

- White rust

- X-ray fluorescence spectroscopy (XRF)

- Yellow chromating

- Yellow chromatography

- Zinc

- Zincate pickle

- Zinc oxide (ZnO)

- Aluminium

- Electroplating

- Chromium-VI and Chromium-III

- Applications

- Corrosion Protection

- Service Condition Scale

- Download

- WIOTEC®

- Contact

In order to optimize and continuously improve our website, we utilize cookies. By continuing to use the website, you consent to the use of cookies. For more information on cookies, please refer to our Privacy Policy.

Wiotec®

Quality Assurance

Assuring the Best Quality

In our modern and future-oriented company, comprehensive quality management is a matter of course.

This requires the coordination of all quality assurance activities, to clearly define them and to align them with established principles. The documentation of the process-oriented quality management in our company is based on the standards DIN EN ISO 9001:2015 and DIN EN ISO 14001:2015.

You are welcome to download our current certificates.

Quality tests in our own laboratory

To ensure the quality of our surface finishes, we carry out on-going quality tests in our in-house test laboratory.

These include, for example, the X-ray fluorescence method in accordance with DIN 50987 and the magnetic induction method in accordance with DIN EN ISO 2178 for testing the layer thickness.

In addition, we offer further tests in cooperation with our partners. These include the following corrosion tests:

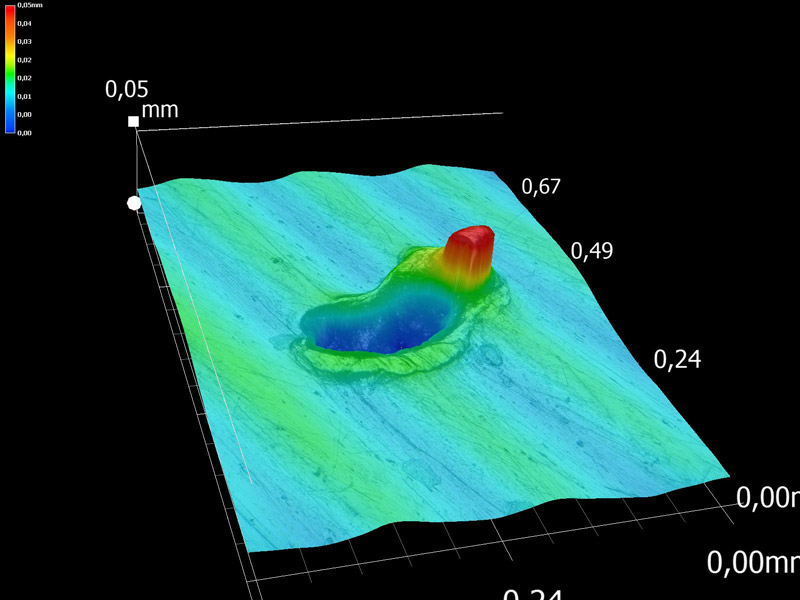

Digital microscopy 3D for inspection and error analysis

Optical microscope with large depth of field and modern 3D measurement functions as well as automatic pore counting for microporous coatings.

Any questions? We’ll gladly assist you ...

Any questions?

We’ll gladly assist you ...

WIOTEC® Ense GmbH & Co. KG

Auf den Geeren 9-11

59469 Ense-Höingen, Germany

WIOTEC® Arnsberg GmbH & Co. KG

Wagenbergstraße 55

59759 Arnsberg, Germany

Phone

+49 2938 97833-0

Fax

+49 2938 97833-20

E-Mail

mailwiotec

From metal to precious metal

The company WIOTEC® is your specialist for surface finishing and metalworking. In our electroplating shop, which is managed according to the latest environmental standards, we are capable of finishing both small parts and long parts of up to six meters. This makes us one of the leading and most efficient decorative surface coaters in Europe.

Our most important resource is our employees - with their commitment, competence and experience. Together with them, we work out and develop individual and tailor-made solutions for our customers. From detailed consultation and planning to purchasing, mechanical and chemical pre-treatment, professional electroplating and supplementary services - WIOTEC®'s range of services leaves nothing to be desired.

© 2023 - WIOTEC® - ALL RIGHTS RESERVED.

© 2023 - WIOTEC® - ALL RIGHTS RESERVED.